Thermo-Mechanical Modelling Of A Steel Ladle Using Periodical Homogenisation for the Refractory Masonries

Abstract

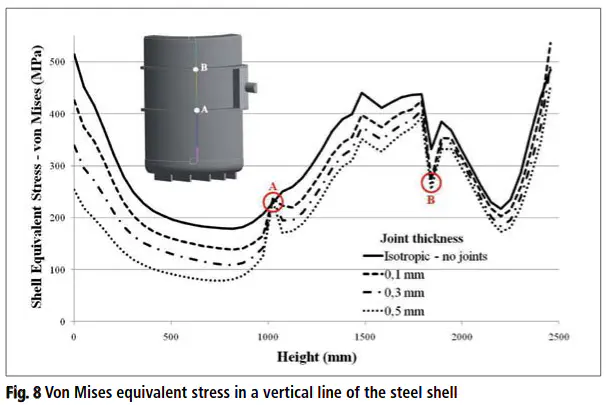

In the steelmaking industry and in many others that involve the processing of molten metal, the metallurgical vessels can be lined with refractory bricks, with or without mortar. These refractory masonries can have different designs (for example parallel or radial for a bottom lining) with different joint thicknesses. The design of these linings poses a complex problem, since the bricks/joints subsystem imposes considerable computational problems due to the large amount of interfaces between them. To compare the influence of these designs on the maximum stresses in the structure, the masonry with dry joints was modelled by a homogeneous equivalent material that takes into account the possibility of joint closure. The thermomechanical properties of this equivalent material were determined using a periodic homogenization method. They are temperature depending and depend in the same time of the joint states (open or closed in the two directions). This masonry model was used to simulate the problem of a complete steel ladle with the finite element method, considering the insulating, safety and working (masonry) linings. It demonstrates the influence of the following parameters: (a) presence or not of joints, (b) thickness of joints, and (c) masonry design. This study brings a help for the design of refractory masonry linings and provides a better estimation of the applicability of a given lining to the thermomechanical loads imposed by operational conditions.